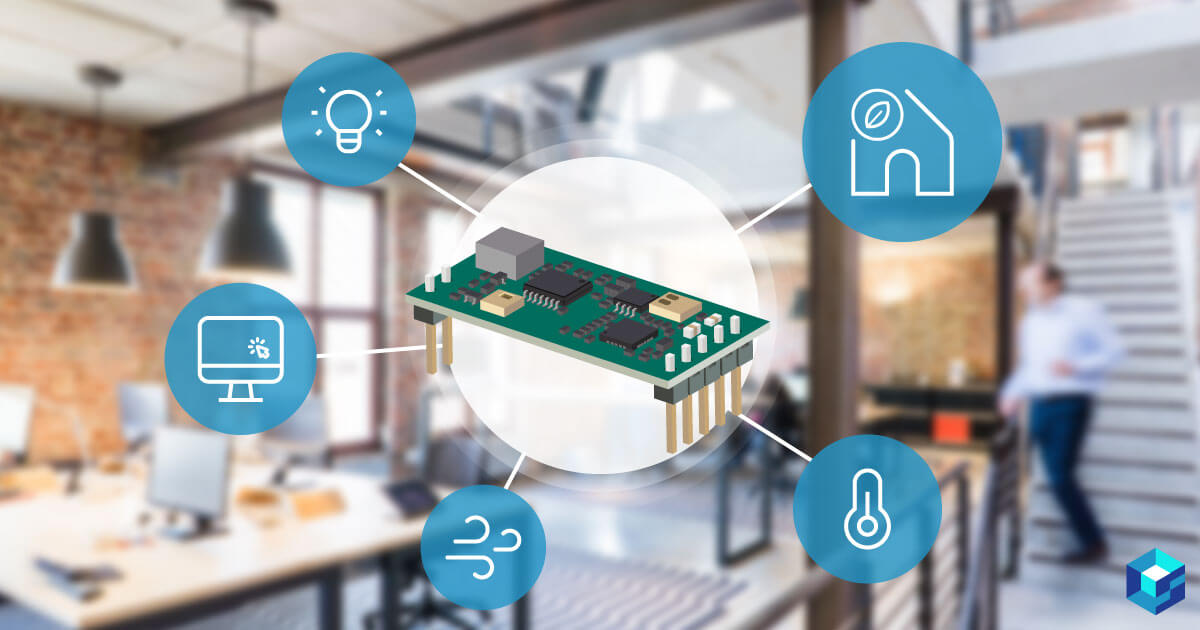

The Internet of Things (IoT), once a fringe element of the electronics industry, has grown exponentially over the past few years. Most people regard IoT technology as the ideal platform for ultra-connected, always online consumer products, including:

- Smart home technology

- Personal health products (wearable tech, heart rate monitors, exercise accessories, etc.)

- Smartphones

- Navigation systems

- And many more

IoT device manufacturers and app developers, meanwhile, have expanded the core concepts of IoT consumer applications to a whole new universe of IoT potential: industrial IoT apps. These connected devices and their surrounding support system (infrastructure, servers, hardware, etc.) now assist everything from factories to farms with more efficient resource usage and optimal energy utilization.

Whether you play a role in supply chain optimization, engineering, research & development, or design, it’s always helpful to know where industrial IoT applications are going – especially considering they’ve come so far in a short amount of time!

The Application Design Process: Implementing Smart IoT Strategies from the Start

How do today’s top industrial IoT designers tackle the many challenges posed by interconnecting a person (or a home or factory or industrial plant) to other interconnected partners, all while providing the most efficient, time sensitive, accurate data?

Here are some design principles evident in the most popular industrial IoT apps and systems:

- Acute environment sensibility. In other words, knowing where your IoT devices and applications are performing is just as critical as how or when. For example, industrial healthcare IoT devices may need to comply with market-specific considerations. An outdoor application requires weatherproof protection without compromising data collection initiatives. That’s probably the first rule in effective IoT design: know your surroundings.

- The lockdown effect. Secure data transfer isn’t just nice to have with industrial IoT devices and applications – it’s an absolute necessity. How secure is your IoT device as a stand-alone entity? Are extra firewalls and built-in security protocols necessary to connect with other systems? Are similar IoT devices subject to piracy, fraud, or compromised data? Start designing with security in mind, instead of the other way around.

- Flexible software integration. Rigidity with industrial IoT applications is a no-win situation. IoT devices need to be flexible and adaptable. This is where a modular, well-developed software infrastructure can help. Code tweaks are a given, but planning out software applications where only a portion of the system needs work – and not the entire configuration – saves time and money on maintenance costs down the road.

- How’s the hardware? The most robust software infrastructure is useless without associated hardware components. This is one area where many IoT developers fall short. Much like security considerations, it’s always recommended to keep hardware in full view. After all, an IoT application is only as strong as its weakest hardware accessory.

- The cost/quality conundrum. Early, middle, and late-stage design review should always include cost/quality considerations. All too often, promising IoT apps have been shortchanged (literally), as design is compromised to save on costs (and vice versa). Thorough pre-planning will enable your IoT app to deliver what you and your customer want: quality products at the lowest possible price.

From Design to Deployment: Popular Industrial IoT Apps

Now that we’ve covered a few critical design aspects of IoT applications, let’s see how some different companies effectively applied those design strategies to deliver practical, workable solutions for all types of industries:

- Maintenance, courtesy of your local robot. Spurred by industrial IoT innovations from companies like Hitachi and ABB, the “smart robot” maintenance minder is becoming more commonplace in factories all across the world. Smart sensors within industrial robots alert staff with important maintenance data, so shutdowns, accidents, and other negative outcomes are prevented altogether. Now that’s a “smart” way to keep factories up and running!

- Intelligent agriculture. Smart farms have been around a while – and they’re getting smarter all the time. Predictive maintenance is a recurring theme with industrial IoT agricultural equipment. And for all the publicity about Uber, Lyft, and Google self-driving vehicles, agricultural equipment manufacturer John Deere actually got the ball (tractor) rolling!

- Mining for IoT gold. The mining industry has been given a big boost by industrial IoT apps, most notably from Japanese industrial vehicle manufacturer Komatsu. Their central IoT command center allows robots and humans to monitor worldwide mining operations in real-time, and the company’s self-driving trucks enable more efficient mineral extraction, from Australia to the United States.

- Factories of the future. In terms of factory performance, the future has already arrived, thanks to industrial IoT apps. Internet-connected sensors, tools, and other accessories increase productivity, all while enhancing overall plant safety. Plus, some smart factories utilize wearable tech accessories (safety gear, glasses, etc.) to prevent accidents and injuries from happening in the first place.

- The ultimate test drive. Many companies enable potential customers to visualize machine and equipment performance before making a purchase. Likewise, client-side simulations can be applied to real-time data to project how a product will perform across a typical lifecycle – or, if the data is useful enough, even longer. In these cases, industrial IoT technology and applications benefit both manufacturer and consumer.

- Addition by division. The utilities industry is notorious for its complicated,ever-expanding power grids. Urban sprawl and sudden population increases make the challenge even harder. But what if companies could sub-divide specific portions of their power grids, enabling swifter, more accurate maintenance procedures? That’s the thinking behind the “microgrid,” and it’s all possible thanks to cutting-edge industrial IoT apps.